Advantages of Single-phase Immersed Dielectric Coolant

In our rapidly advancing technological landscape, efficient cooling methods are crucial. From data centers to electric vehicles, managing heat generation is key to maintaining performance and extending the lifespan of devices. This is where single-phase immersed dielectric coolants come into play, offering a modern solution to an age-old problem.

What is Single-phase Immersed Dielectric Coolant?

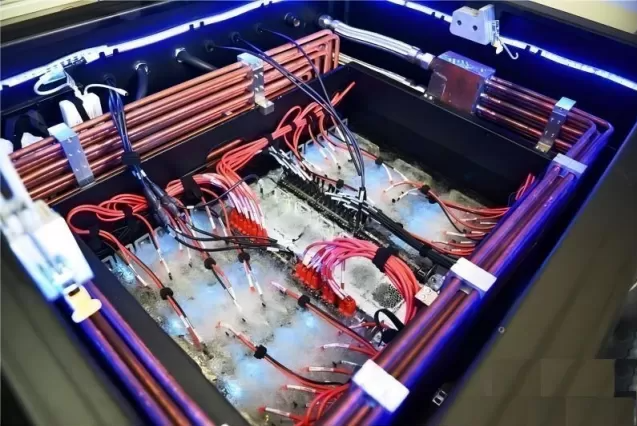

Single-phase immersed dielectric coolant is a specialized cooling method where electrical components are submerged in a dielectric fluid. Unlike traditional cooling systems, this method allows for direct contact between the coolant and the heat-generating parts, enhancing heat dissipation and improving overall efficiency.

Advantages of Single-phase Immersed Dielectric Coolant

Enhanced Cooling Efficiency

One of the primary benefits is the superior cooling efficiency. By immersing components directly in the coolant, heat is transferred more effectively compared to air or indirect liquid cooling systems. This results in lower operating temperatures and improved performance.

Safety and Reliability

Dielectric fluids are non-conductive, meaning they prevent electrical short circuits, ensuring safety. They also offer better protection against environmental factors like dust and humidity, which can compromise traditional cooling systems.

Environmental Benefits

Using OSi SiFO Coolsingle-phase immersed dielectric coolants can lead to significant environmental benefits. These coolants often require less energy to maintain optimal temperatures, thereby reducing the overall energy consumption and carbon footprint of the systems they cool.

Applications in Technology

Data Centers

Data centers are among the largest consumers of cooling technologies. Implementing dielectric coolants can dramatically reduce the energy required for cooling, making data centers more sustainable and cost-effective.

Power Electronics

Power electronics, including transformers and power supplies, benefit greatly from the improved cooling efficiency of dielectric fluids. This leads to enhanced performance and longevity of these critical components.

Electric Vehicles

In electric vehicles, efficient cooling is essential to maintain battery performance and longevity. Dielectric coolants provide a reliable solution to keep batteries and power electronics at optimal temperatures.

How Single-phase Immersed Cooling Works

The Immersion Process

In this cooling method, components are fully submerged in a dielectric fluid. This direct immersion allows for efficient heat transfer from the components to the fluid.

Heat Dissipation Mechanics

The heat generated by the components is absorbed by the dielectric fluid and then dissipated through various means, such as natural convection or additional cooling mechanisms like radiators or heat exchangers.

Types of Dielectric Fluids Used

Synthetic Fluids

Synthetic dielectric fluids are engineered for high performance and stability. They offer excellent thermal and electrical properties, making them ideal for high-demand applications.

Natural Ester Fluids

Natural ester fluids, derived from renewable sources, are environmentally friendly options. They offer good performance while being biodegradable and non-toxic.

Mineral Oils

Mineral oils are a cost-effective option, widely used due to their availability and reliable performance in various cooling applications.

Comparison with Traditional Cooling Methods

Air Cooling

Air cooling is one of the most common methods but is less efficient compared to liquid cooling systems. Air's lower thermal conductivity makes it less effective at removing heat.

Liquid Cooling Systems

Traditional liquid cooling systems use water or glycol mixtures and rely on heat exchangers. While more efficient than air cooling, they still can't match the direct heat transfer capabilities of dielectric immersion cooling.

Environmental Impact

The use of single-phase immersed dielectric coolants leads to reduced energy consumption. This is not only beneficial for operational costs but also contributes to a lower carbon footprint, aligning with global sustainability goals.

Cost-effectiveness

Initial Investment vs. Long-term Savings

While the initial setup cost for dielectric cooling systems can be higher, the long-term savings in energy consumption and maintenance can make it a cost-effective solution.

Maintenance Costs

Maintenance of dielectric cooling systems tends to be lower compared to traditional methods, as the non-conductive fluids reduce the risk of component failure and require less frequent servicing.

Challenges and Limitations

Potential Issues

Despite the advantages, there are potential challenges such as fluid leakage or the need for specialized equipment to handle dielectric fluids safely.

Current Research and Developments

Ongoing research aims to address these challenges, with advancements in fluid formulations and system designs that enhance performance and reliability.

Innovations in Dielectric Coolant Technology

Latest Advancements

Recent innovations include the development of more efficient dielectric fluids and improved system designs that maximize cooling efficiency and minimize environmental impact.

Future Prospects

The future looks promising with continuous improvements in dielectric coolant technology, potentially revolutionizing cooling solutions across various industries.

Implementing Dielectric Coolant Systems

Steps to Integrate into Existing Systems

Integrating dielectric cooling systems involves careful planning and execution. Key steps include system design, fluid selection, and ensuring compatibility with existing infrastructure.

Best Practices

Adopting best practices, such as regular monitoring and maintenance, ensures optimal performance and longevity of the cooling system.

Conclusion

Single-phase immersed dielectric coolants represent a significant advancement in cooling technology. With their superior efficiency, safety, and environmental benefits, they are poised to become the preferred choice for cooling solutions across various industries. As technology continues to evolve, we can expect even greater innovations and wider adoption of this cutting-edge cooling method.

For more information please contact OSi Holding limited